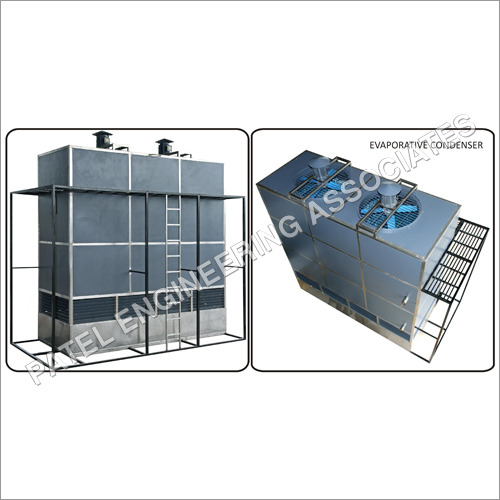

About Evaporative Condenser

We are among the most respectable firms, engaged in manufacturing and supplying our prestigious patrons with Evaporative Condenser. Precisely designed, these products are made using quality components and material that are procured from the most trusted and certified vendors of the market. Also, our offered Evaporative Condenser is provided to customers in different models at market leading prices. These products can also be customized as per the demands and needs of clients within the promised time.

Features:

- Sturdy construction

- Low maintenance

- Easy installation

Other information:

- The Evaporative Condensers have the capability to save more energy in comparison with PHE or Shell & Tube type condensers. Around 15 - 20% of the energy can be saved owing to the 10 - 15% power saving in compressor motor and approx 75% power saving in condenser pumps by maintaining a considerably low temperature for condensing.

- We have resolved the issues with Evaporative Condensers like cleaning of tubes by providing sufficient space between tubes. The corrosion problem of casing and tubes is solved by providing SS or FRP casing and SS tubes.

Outstanding Heat Exchange & DurabilityAchieving over 90% heat exchange efficiency, this evaporative condenser utilizes quality materials such as seamless stainless steel or tube finned copper coils, and a robust galvanized steel structure with corrosion-resistant finishes. Its service life exceeds 15 years with regular maintenance. Ambient humidity tolerance up to 95% RH ensures reliability in harsh climates.

Efficient Water and Energy UseThe innovative spray system delivers uniform water distribution, lowering water consumption through a carefully designed cycle. The enclosed induction motor and efficient water circulation pump contribute to reduced energy costs, while the noise control system maintains sound pressure below 70 dB(A), ensuring a quieter operational environment.

Simple Installation and MaintenanceDesigned for outdoor rooftop or ground-mount setups, installation is straightforward thanks to customizable packing options and standard flanged connections. Maintenance is hassle-free with easy-access doors for coil cleaning and servicing. The PLC-based control panel allows for both automatic and manual operation, streamlining daily user interaction.

FAQs of Evaporative Condenser:

Q: How does the evaporative condenser minimize water usage during operation?

A: The condenser uses a highly efficient spray system that ensures uniform water distribution and optimizes the evaporative cooling cycle, thus reducing total water consumption compared to conventional systems.

Q: What maintenance processes are required and how easy is servicing this condenser?

A: Routine maintenance involves coil cleaning and checking water distribution, which are simplified by easy-access service doors. Servicing and maintenance tasks are further facilitated by accessible design and PLC-controlled monitoring.

Q: Where can this evaporative condenser be installed for optimal performance?

A: It is ideally suited for outdoor rooftop or ground-mounted installations, with options for customized packing and flexible inlet/outlet flanged connections to fit varying site requirements and capacities.

Q: What safety features are incorporated to ensure reliable operation?

A: Safety mechanisms include overload protection for the motor and an anti-frost device, safeguarding the unit during extreme conditions and preventing operational hazards.

Q: What are the typical applications and benefits of using this condenser in industrial environments?

A: Common applications include cold storage, food processing, ice and chemical plants. Benefits include high cooling capacity (100900 kW), longevity, reduced water and energy use, and robust corrosion-resistant construction.

Q: Which materials are used in the construction to enhance the condensers durability and lifespan?

A: The unit employs galvanized steel for the framework, high-quality seamless stainless steel or tube finned copper for the cooling coils, and a stainless steel drain pan with anti-corrosion coating, ensuring durability and long service life.

Q: How can users control and monitor the operation of the condenser?

A: A PLC-based control panel supports both automatic and manual operation, providing users with flexibility and precision to adjust performance and monitor the system efficiently.