About Heat Exchanger

Backed by our efficient workforce, we are able to design and supply Heat Exchanger to our esteemed clients. We design all the products using premium grade raw material and modern technology to assure that final output meets with international quality standards. To improvise the existing products, our R&D experts also conduct proper market research. Further, our logistics personnel help us in delivering Heat Exchanger at clients end within the set time frame.

Features:

- Sturdy construction

- Corrosion and abrasion resistant

- Easy to operate and maintain

Other information:Heat Exchanger

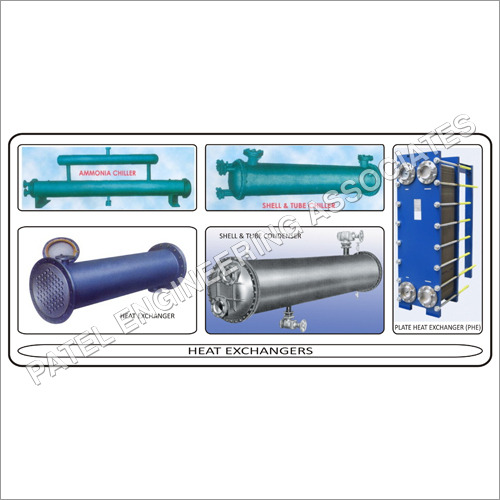

We design and supply various type of Heat Exchangers such as,

Shell & Tube type

Finned Tube type

PHE type

Atmospheric Condensers for Ammonia

Designed for high-capacity process cooling and heating, this heat exchanger manages up to 2000 liters per hour and withstands rigorous operational pressures. Its stainless steel construction aids in durability and resistance to corrosion, ensuring prolonged service life even in challenging conditions common to Indian industries.

Flexible Installation and Maintenance OptionsThis unit features horizontal, floor-mounted installation with flanged connections for seamless integration. Choose between manual or automatic cleaning methods to simplify maintenance and minimize downtime, supporting continuous operation and improved productivity in industrial setups.

FAQs of Heat Exchanger:

Q: How does the counter flow heat exchange type benefit industrial processes?

A: The counter flow design enhances thermal efficiency by allowing maximum temperature differential between the hot and cold fluids, resulting in improved heat transfer and energy savings.

Q: What is the recommended method for cleaning this heat exchanger, and how often should it be performed?

A: You can clean the unit using manual or automatic techniques based on site preference. Regular cleaningsuch as every few monthshelps maintain optimal performance, especially in processes with scaling or fouling risks.

Q: Where is the optimal placement for installing this heat exchanger in an industrial setting?

A: It is best installed horizontally on the floor, near the relevant process line or equipment, with sufficient clearance for maintenance and easy access to flanged end connections.

Q: What is the process for integrating the unit into existing systems?

A: Integration involves connecting the heat exchanger to your liquid circuit using the supplied flanged connections, ensuring voltage compatibility (220 V), and confirming pressure ratings with your process specifications.

Q: When should the heat exchanger be operated at its maximum capacity and pressure?

A: Operate at maximum capacity (2000 L/hr) and pressure (15 Bar) during peak industrial loads, but ensure system compatibility and safety checks are in place to prevent overpressure incidents.

Q: What types of industrial applications benefit most from this heat exchanger?

A: It is ideal for process cooling and heating tasks in various industries, including chemical, pharmaceutical, and food processing, especially where efficient thermal management and corrosion resistance are required.

Q: What are the key usage benefits of choosing Stainless Steel 304 for this equipment?

A: Stainless Steel 304 offers high corrosion resistance, easy cleaning, and robust durability, making the heat exchanger ideal for demanding industrial environments with exposure to aggressive fluids.