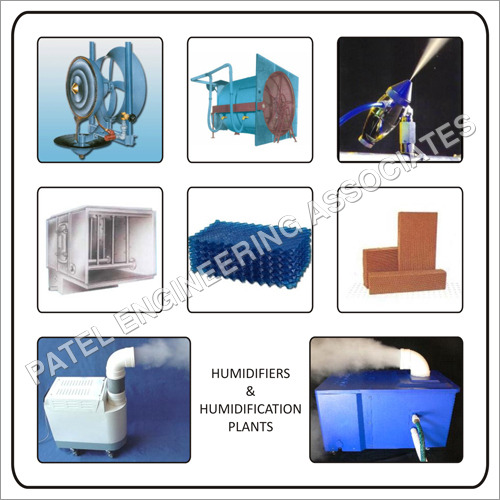

About Humidifier And Humidification Plant

Being a customer centric organization, we are engaged in manufacturing and supplying Humidifier And Humidification Plant. All these products are widely used in textile industry, cold storages, cotton ginning mills and green houses. These products are provided to customers in different models and specifications at most competitive prices. Also, we provide tailor-made solution for our Humidifier And Humidification Plant.

Features:

- Less power consumption

- Easy operations

- Low maintenance

We design or supply various type of Humidifiers as well as Humidification Plants for Textile Industries, Cold Storages, Cotton Ginning Mills & Green Houses.

Types:

- Spray type

- Cellulose pad type

- PVC honey comb fills type

- Spot humidifiers

- Semi central units

- Foger type

- High pressure atomizer type

Applications:

- Textile industries

- Cold Storages

- Green Houses

- Tea Gardens

- Cotton Ginning Mills

Efficient Humidification for Large SpacesOur industrial humidification plant utilizes advanced high-pressure atomization and PLC/microprocessor control to deliver precise humidity for areas up to 10,000 sq. ft. With multi-stage filtration, automated operation, and digital humidity display, this system offers reliable performance for industries where accurate moisture control is critical.

Robust Design and Safety FeaturesBuilt from powder-coated stainless or mild steel, the unit resists corrosion and is designed to withstand demanding environments. The floor-mounted shape fits seamlessly in commercial and industrial settings. Integrated overload protection, dry run safety, and automated shutdown ensure operational safety and longevity.

Customizable and Low-Maintenance SolutionWith customizable color and material options, this humidification plant suits diverse industry standards. The automatic drainage system, low noise level, and minimal maintenance requirements offer hassle-free, energy-efficient operation. Accessories like water filters and high-quality nozzles further enhance reliability.

FAQs of Humidifier And Humidification Plant:

Q: How does the humidification control system work in this plant?

A: The control system uses microprocessor or PLC-based technology to automatically monitor and adjust humidity levels within your set range (30%-95% RH). Changes are displayed digitally, ensuring the environment stays consistent without manual intervention.

Q: What is the process for installing the humidification plant?

A: Installation involves connecting the plant to a standard 1-inch water inlet and ensuring proper floor mounting. The automated drainage system and multi-stage filtration must be set up according to the provided guidelines, usually managed by certified technicians for hassle-free commissioning.

Q: Where can this industrial humidification plant be used?

A: Its designed for use in textile factories, pharmaceutical production, packaging, and processing plants. The plant is also suitable for commercial and agricultural environments that require effective humidity regulation over large coverage areas.

Q: When does the automated shutdown feature activate?

A: The automated shutdown is triggered during overload conditions, dry runs, or any operational anomaly detected by the safety sensors. This prevents damage to the unit and ensures user safety at all times.

Q: What are the benefits of high-pressure atomization technology in this system?

A: High-pressure atomization allows the plant to effectively disperse water into fine droplets, which increases humidity rapidly and evenly across large spaces. This ensures energy-efficient operation and optimal moist air quality for industrial and commercial applications.

Q: How do I maintain the humidification plant to ensure long-term reliability?

A: Maintenance is minimal thanks to features such as automatic drainage and multi-stage filtration. Regular inspections of nozzle integrity, filter condition, and control panel calibration are recommended to keep the system operating smoothly.

Q: What accessories are included with the humidification plant?

A: The system comes equipped with essential accessories, including high-quality nozzles (brass/stainless steel), water filters, a control panel, and other optional features tailored to your requirements for seamless operation.